-

Highlight

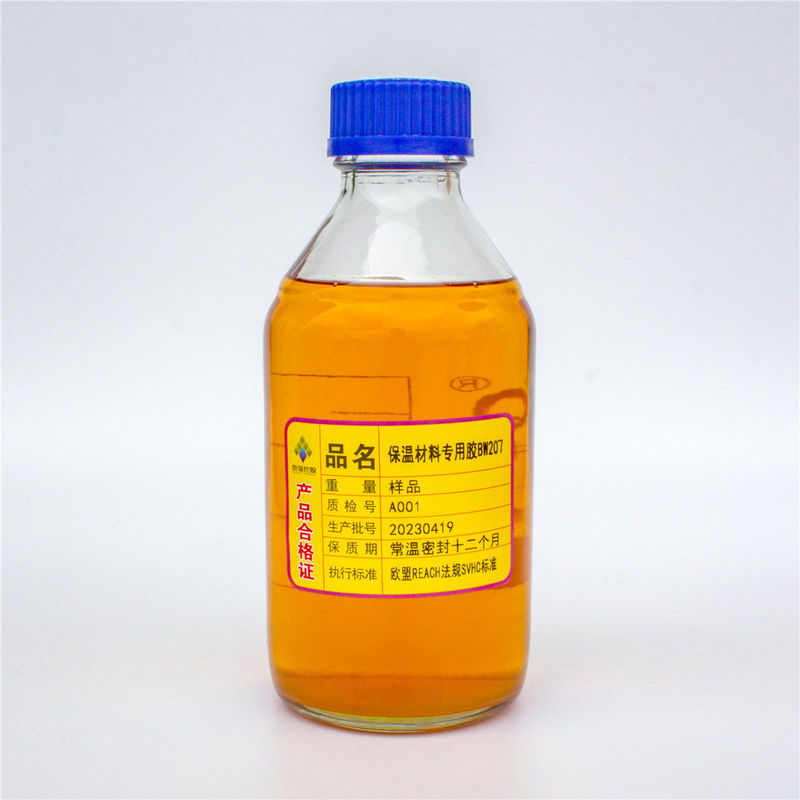

Insulation Board Adhesive HVAC

,UN1133 Insulation Board Adhesive

,UN1133 adhesive for polystyrene insulation

-

ClassificationUN1133

-

Main Raw MaterialNeoprene

-

UsageThermal Insulation Applications

-

AppearanceBlack Or Yellow

-

Solid Content20±1

-

Viscosity Cps (25℃)350-500 Mpa.s

-

Gravity0.87-0.92

-

OEMYes

-

Place of OriginGuangdong, China

-

Brand NameTAIJIA

-

Model NumberBW207-666

-

Minimum Order Quantity4000 kilograms

-

Price$1.50 - $2.20/kilograms

-

Supply Ability300 Ton/Tons per Day

UN1133 Insulation Board Adhesive

Product Description

Key Features:

1. Superior Bonding Strength: Our adhesive offers exceptional bonding strength, ensuring a durable and reliable connection between insulated ducting components. It creates a strong bond that can withstand the rigors of HVAC systems.

2. Excellent Thermal Stability: The adhesive is engineered to maintain its integrity under extreme temperature conditions. Whether exposed to high heat or sub-zero temperatures, it remains stable, preventing any degradation of the bond and ensuring long-lasting performance.

3. Flexible and Versatile: This adhesive is formulated to accommodate the movement and expansion of insulated ducting. Its flexibility allows for easy installation, even on curved or irregular surfaces, providing a secure seal without compromising the ducting system's integrity.

4. Compatibility with Various Insulation Materials: Our adhesive is compatible with a wide range of insulation materials commonly used in HVAC applications, including fiberglass, foam, rubber, and foil-faced insulation. This versatility ensures that you can confidently use our adhesive with different types of insulated ducting systems.

5. Quick Cure Time: The adhesive features a fast-curing formula, reducing downtime during installation. It cures rapidly, allowing for efficient assembly and accelerated project timelines.

6. Low VOC Content: We prioritize environmental sustainability by formulating our adhesive with low Volatile Organic Compound (VOC) content. This ensures compliance with industry regulations and contributes to healthier indoor air quality.

7. Easy Application: The adhesive comes in user-friendly packaging, enabling convenient application. Whether using a brush, roller, or spray, it applies smoothly and evenly, facilitating efficient coverage and minimizing wastage.

8. Longevity and Durability: Our premium adhesive is engineered to withstand the extended service life of HVAC systems. It resists aging, cracking, and deterioration, providing a long-lasting bond that ensures the integrity of insulated ducting throughout its operational lifespan.

Application Instructions:

1. Ensure both surfaces to be bonded are clean, dry, and free from dust, grease, or other contaminants.

2. Apply a thin, even layer of adhesive to one surface using a brush, roller, or spray.

3. Align the surfaces and firmly press together to achieve maximum contact and adhesion.

4. Allow sufficient curing time as per the manufacturer's guidelines before subjecting the bonded materials to mechanical stress or temperature variations.

Note: For specific instructions and safety precautions, please refer to the product's technical data sheet and Material Safety Data Sheet (MSDS).

| Appearance | Black or yellow viscous liquid |

| Shelf life | 12 Month |

| Solid content | 20±1 |

| Viscosity cps (25℃) | 350-500 mpa.s |

| Gravity | 0.87~0.92 |

| Heat resistance | ≥60℃ |

| Odor | Light soft odor |

| MOQ | 4000kg |

![]()

![]()

![]()